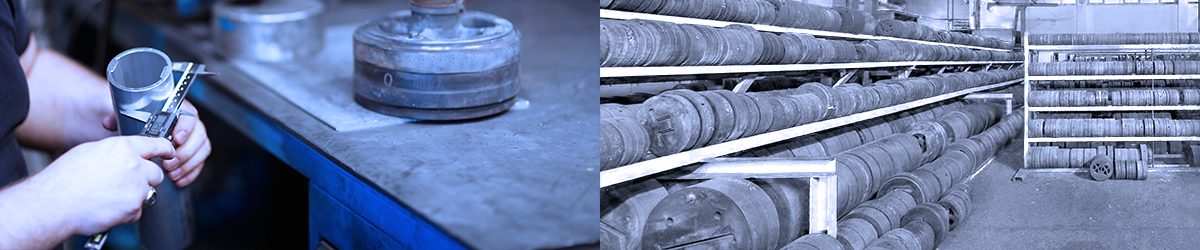

Ekstrüzyon pres hattımızda nitelikli ekipmanlarımız ve geleceği karşılayan teknolojik altyapımızla dayanıklı alüminyum profillerinin üretimini gerçekleştirmekteyiz. Bu doğrultuda geliştirdiğimiz döküm hattımız ve alüminyum ekstrüzyon yatırımımızla üretim yetkinliklerimizi güçlendiriyor, müşterilerimizin taleplerini hızlı ve verimli bir şekilde cevaplıyoruz.

Ekstrüzyon Hattımızdaki Yetkinliklerimiz:

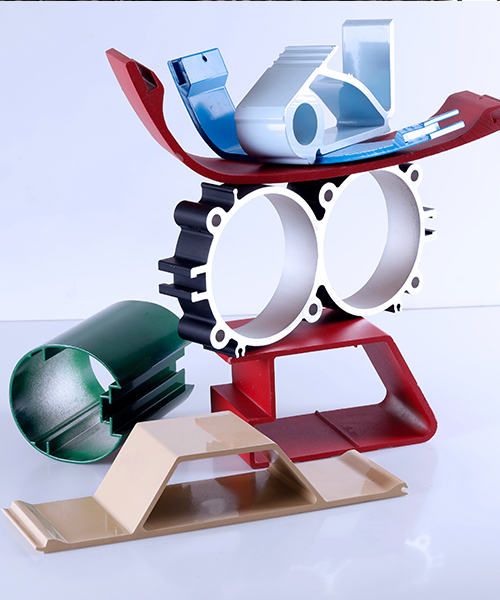

• 300 mm Çapında Boru Profil Üretebilme Kabiliyeti

• 450 mm Genişliğinde Lama Profil Üretebilme Kabiliyeti

• 210 x 210 mm Kutu Profil Üretebilme Kabiliyeti

• 410 x 80 mm Dikdörtgen Kutu Profil Üretebilme Kabiliyeti

• 200 mm Çapında Dolu Çubuk Üretebilme Kabiliyeti

• 80 kg Ağırlığına Kadar Profil Üretebilme Kabiliyeti

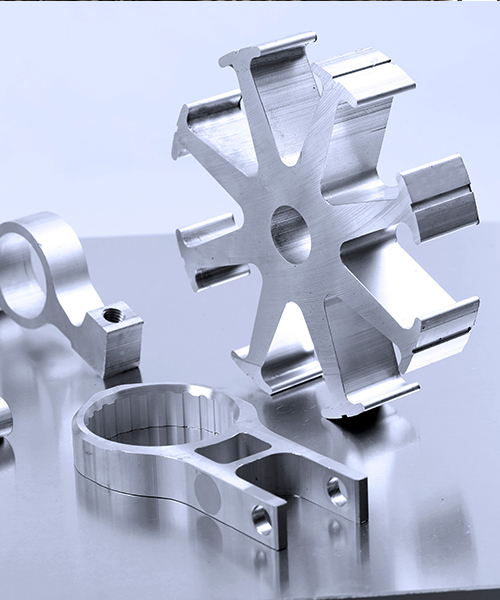

• İzotermal Ekstrüzyon Kabiliyeti

• 1600 mm Boyunda Bilek Ekstrüze Edebilme Kabiliyeti

• 250 Ton Germe Kuvveti ile Yüksek Mukavemetli Profilleri Gerdirebilme Kabiliyeti

• 62 m Tezgâh Uzunluğu

• 18 m Profil Termik Kabiliyeti

• Yıllık 15.000 Ton Profil Üretebilme Kabiliyeti

40 MN (10’’) DANIELI – BREDA EKSTRÜZYON PRES HATTI

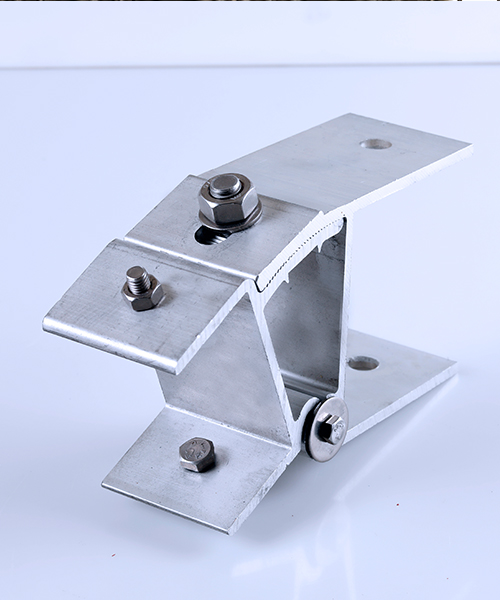

Yeni fabrikamızda yer alan “Büküm ve Şekillendirme – Solar Çerçeve” hatlarımız ve alanındauzman mühendislerimizden oluşan deneyimli ekibimiz ile kontrollü bir üretim sürecinin tüm aşamalarını titizlikle düşünüyoruz. Alüminyumun gücünü tüm sektörlerde verimli bir şekilde kullanabilmek için tam donanımlı tesislerimizle geleceği karşılıyoruz.

40 MN (10’’) Danieli – Breda Ekstrüzyon Pres Hattı Özellikleri:· Danieli – Breda 4.000 Mton İzotermal Ekstrüzyon Pres

· KAUTEC Bölge Kontrollü Biyet Fırını

· KAUTEC Değişken Soğutma Kontrollü Soğutma Sistemi

· KAUTEC 125 Metre Profil Masası ( 220 Ton Gergi Hattı)

· 26 Metre Yaşlandırma Fırını

· Hava – Yağ Akışkanlı Biyet Döküm Teknolojisi

· 300 mm x 450 mm Kesit Ebatlarında Profil Üretimi

· 6082-6005-6063 -6061-6101-6351-1050-1070-1350 Alaşımlarında Üretim

· T6–T5–T4–T651–T66 Temper Uygulamaları