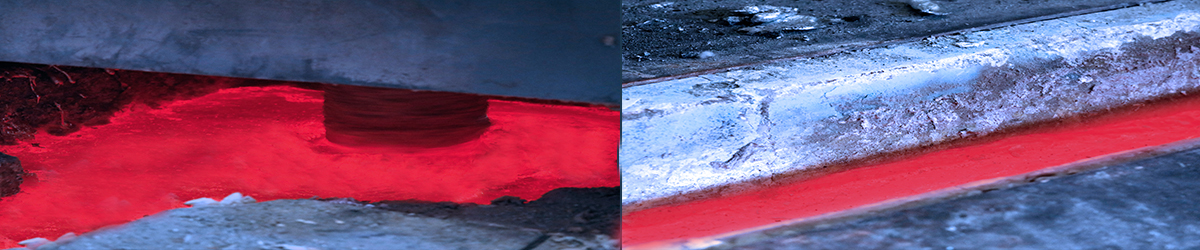

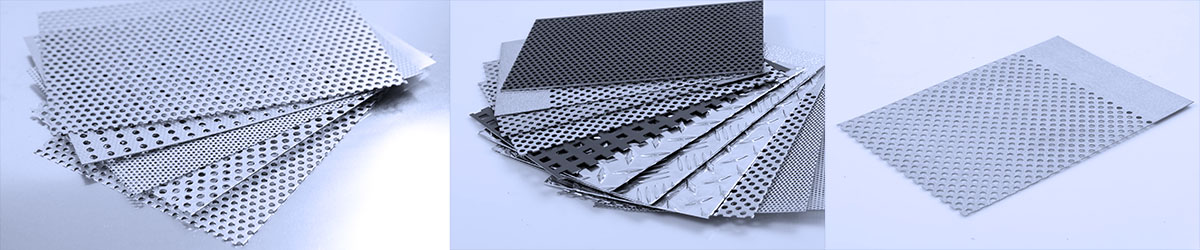

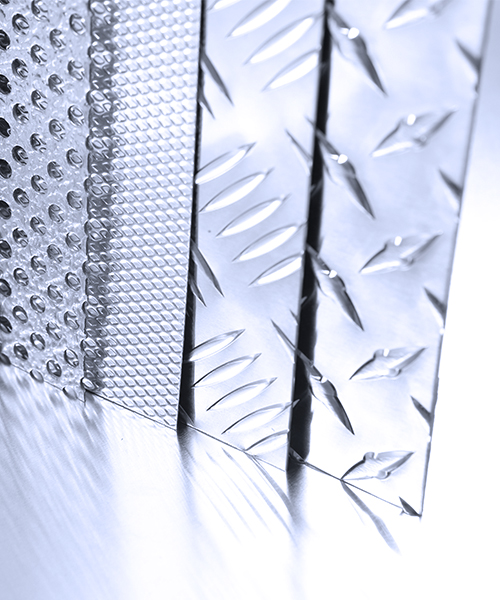

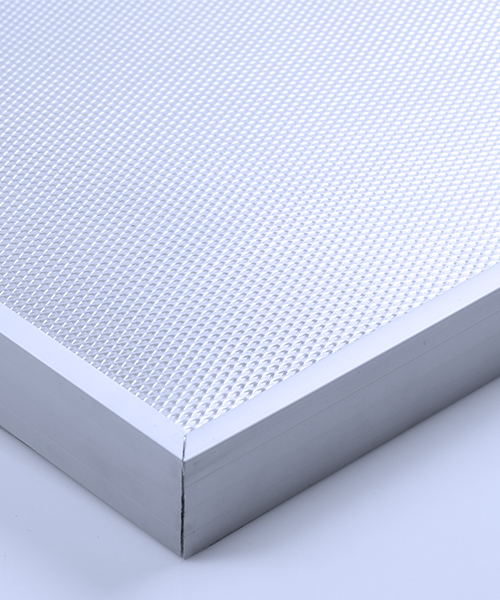

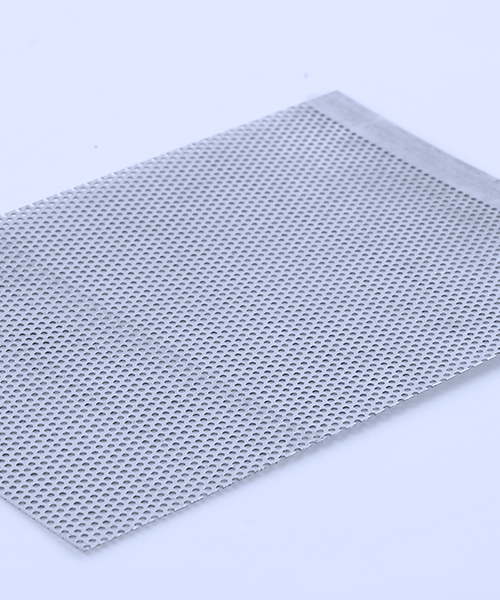

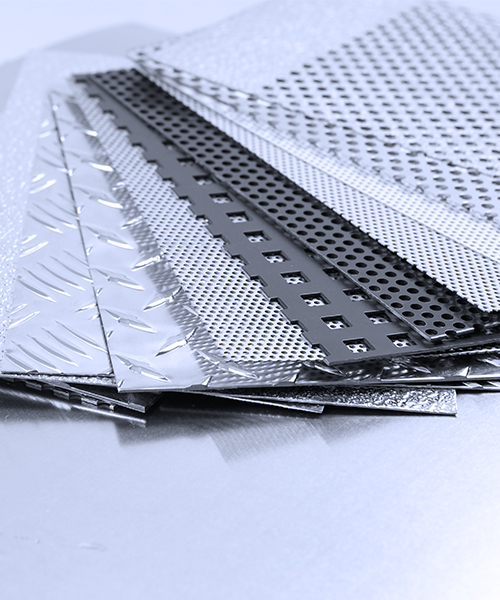

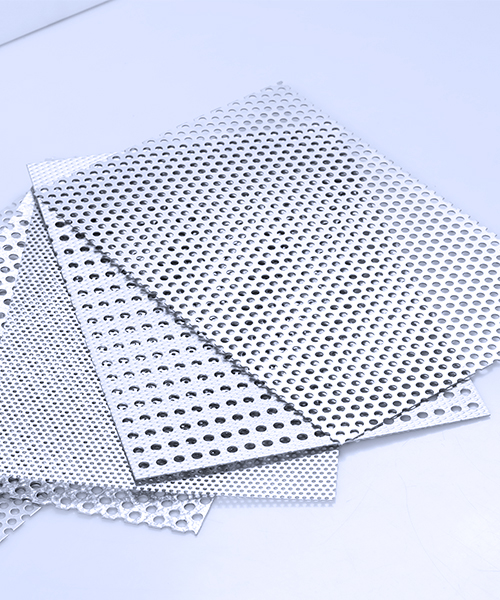

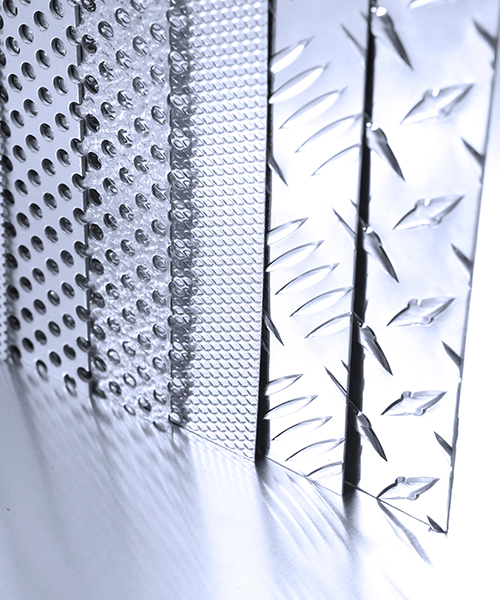

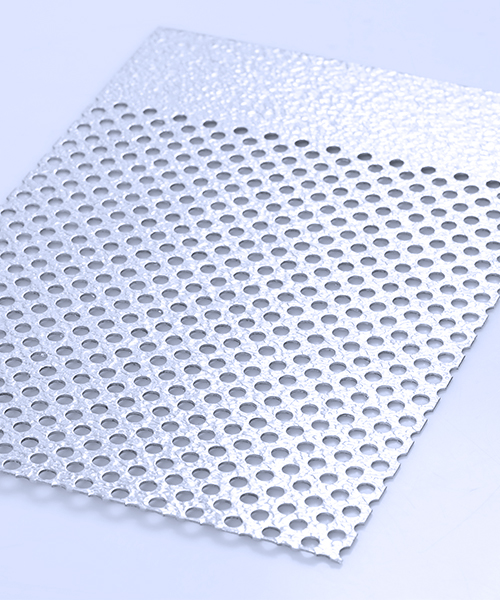

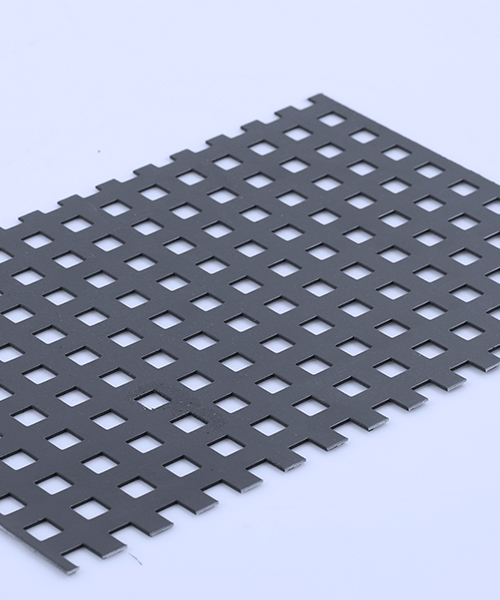

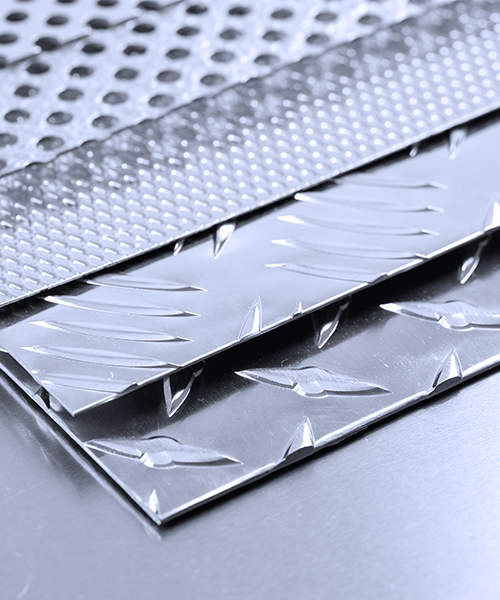

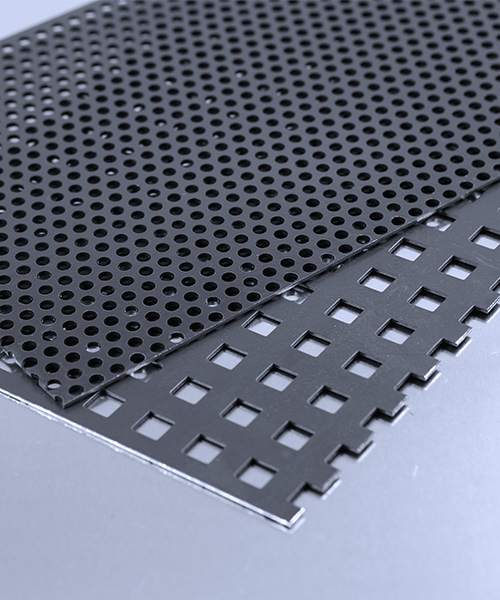

PMS plate facility provides the highest quality service to its business partners with its laboratory where all its products are tested, as well as continuous casting lines, cold rolling, annealing furnaces, washing-stretching, slitting and cut-to-length lines. Our machinery;